Our team in action.

Everyday Blade Case Study

Successfully funded on

HOW DID WE DO IT?

Step 1: Product Definition

We meticulously analyzed market needs, user preferences, and business goals to define the scope, features, and requirements of this new product. This phase is crucial as it established a clear direction for the development team, aligned stakeholders on the product's purpose, and ensured that the design and development efforts were targeted towards creating a solution that not only met customer needs but also aligned with the overall strategic objectives of the company.

The Problem

In the current pocket knife market landscape, users encounter several pain points that hinder the overall satisfaction and practicality of their experience. Traditional pocket knives, while functional, present challenges that our target audience finds increasingly frustrating. These pain points include the substantial pocket space occupied by most commonly carried knives, the need for additional tools and complex processes for sharpening, the excessive size for routine tasks like cutting boxes, and the inherent risk of misplacement or forgetfulness.

-

Existing pocket knives tend to take up a significant amount of pocket space, impacting the user's comfort and mobility. This poses a challenge for individuals who seek a compact and easily portable cutting solution.

-

Users often struggle with the sharpening process of traditional pocket knives, which requires extra tools and difficult to master techniques. This proves to be inconvenient and time-consuming, discouraging regular maintenance and leading to a decline in the knife's performance over time.

-

Many pocket knives on the market offer features that are more than necessary for everyday tasks such as cutting boxes and opening packages. Users seek a solution that is specifically tailored to their daily needs without unnecessary complexities.

-

Conventional pocket knives can be easily misplaced or forgotten at home. Users face the frustration of not having a reliable cutting tool at hand when needed, impacting their overall convenience and preparedness.

Market Analysis

-

We began by studying current industry trends, focusing on everyday users, outdoor enthusiasts and craftsmen. Through user research and testing, we identified a growing demand for a more versatile, durable, and easy-to-maintain tool. Competitor analysis revealed a gap in the market for pocket knives that combine a small footprint with a convenient replaceable blade system. Through competitor testing, we rigorously compared existing products, assessing blade sharpness and shape, durability, ergonomics, and material quality. Through demographic research we identified who needs this tool and the overall market size. This process helped us refine the knife’s unique features and allowed us to create a comprehensive requirements list that outlined the product development path.

Step 2: Ideation

-

In the ideation phase, our experienced product development consultancy team engaged in dynamic brainstorming sessions, leveraging diverse perspectives and industry insights to generate innovative concepts. During the ideation phase, our design team concentrated on developing a minimally viable product (MVP) that met all core requirements while ensuring functionality, durability, and ease of use. We explored various opening mechanisms—ranging from traditional manual designs to never before seen one-handed systems—ensuring seamless operation in any scenario. We also investigated different manufacturing processes, evaluating cost-effectiveness, quality, and scalability. The team worked to optimize the design for these processes, ensuring that every component, from the replaceable blade system to the handle construction, could be efficiently produced without compromising on performance or aesthetics. Through this exploration, we discovered an innovative blade locking system, selected a scalable manufacturing process and identified an overall architecture that minimizes the number of components and assembly time.

Step 3: Concept Development

-

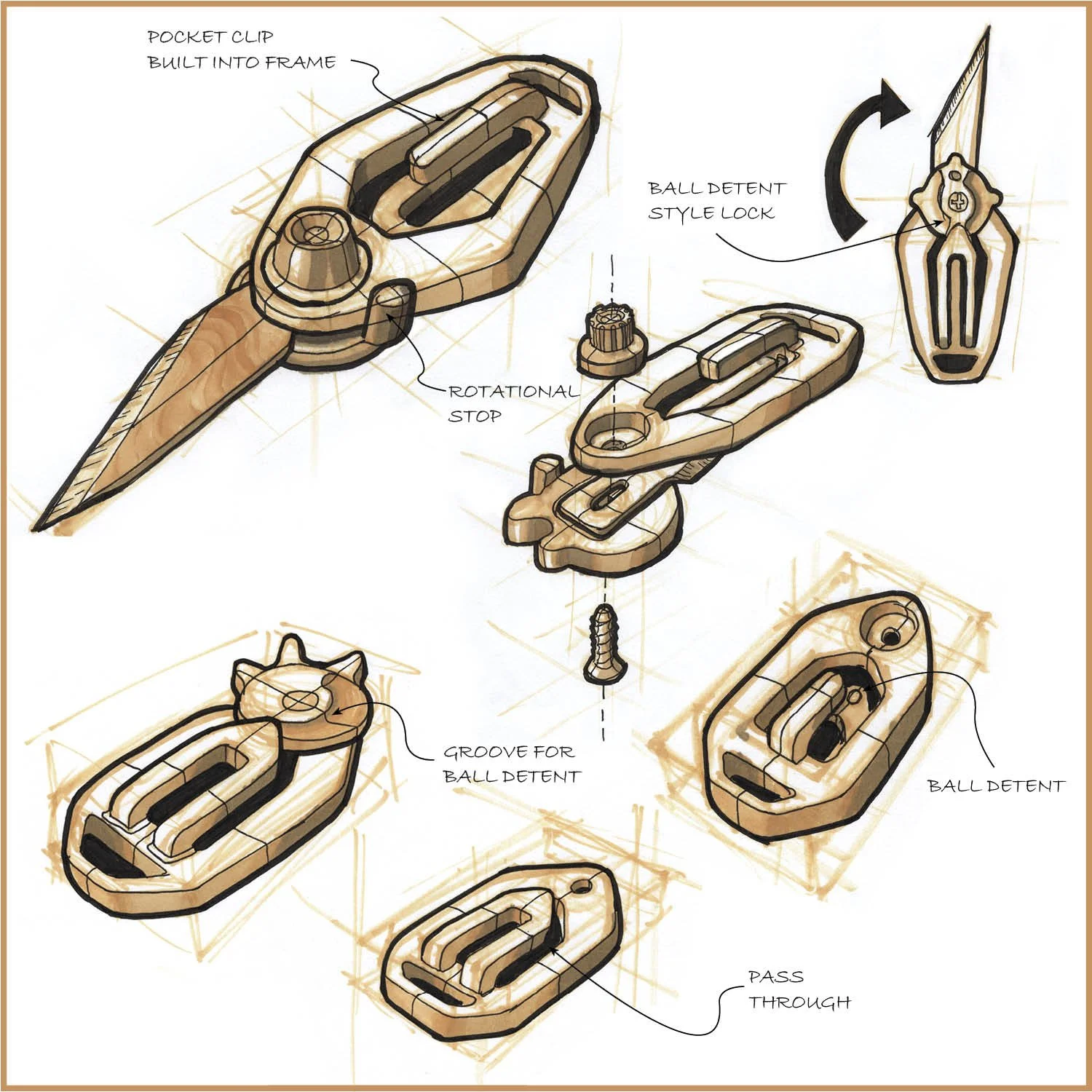

During the concept development phase, the design team created detailed sketches and drawings to visually communicate how the knife would function and look. These illustrations highlighted the key mechanics, such as the replaceable blade system and opening mechanism, while also show casing a simple form that can be quickly 3D modeled in our engineering software. The focus was on ensuring the concept was practical, aesthetically pleasing, and met user needs. These drawings served as the blueprint for the next step in the process, providing a clear direction for the CAD phase, where the design would be digitally modeled.

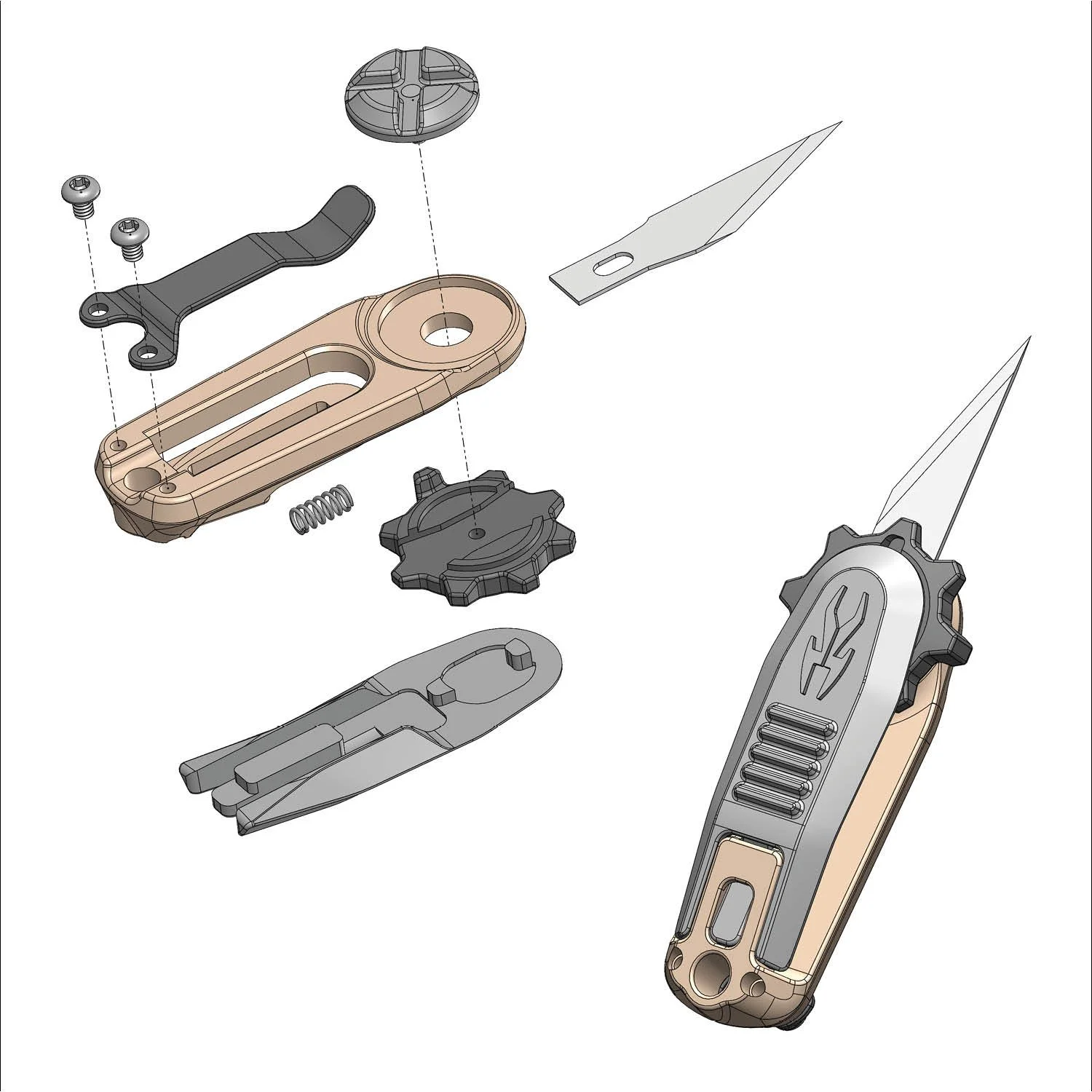

Step 4: Computer Aided Design

-

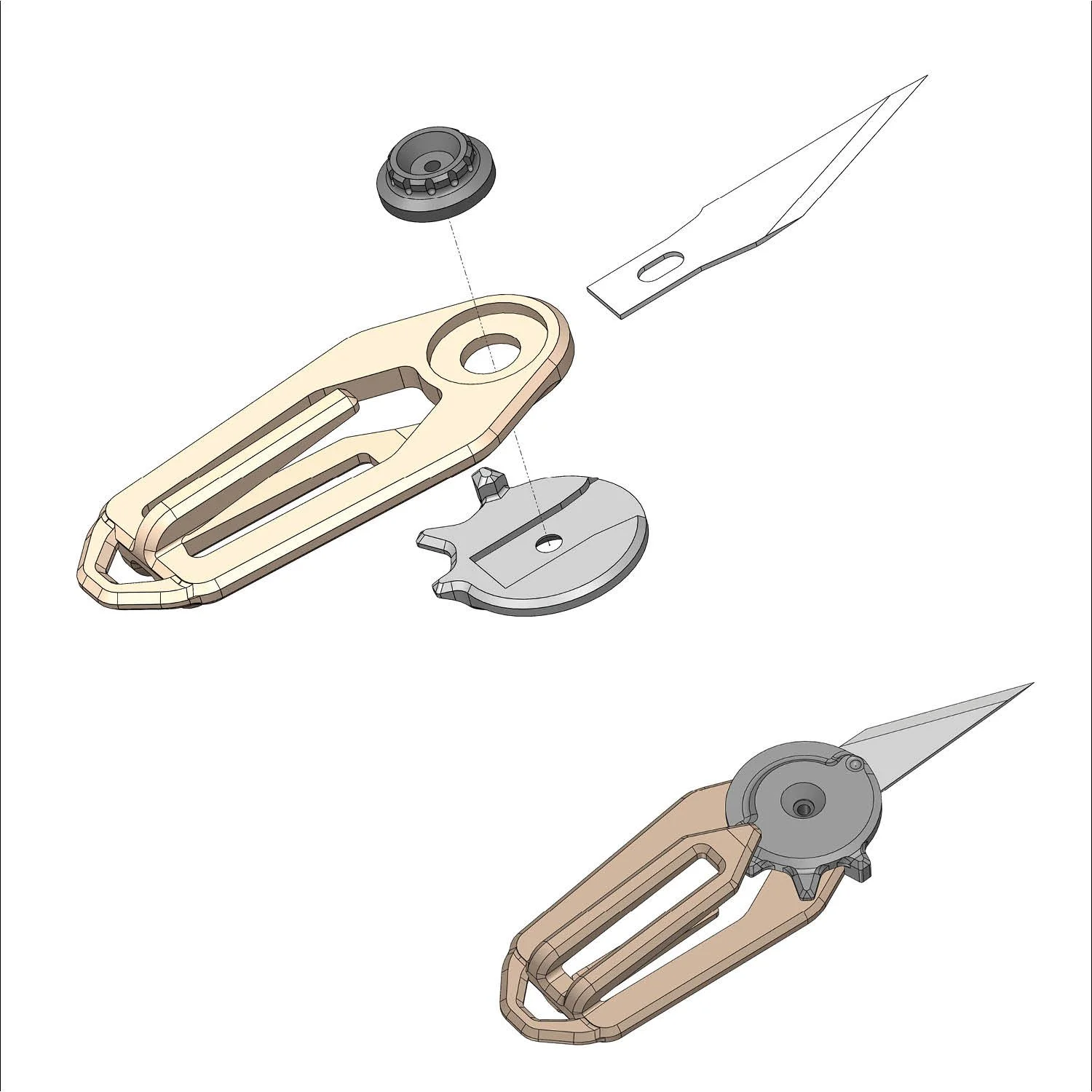

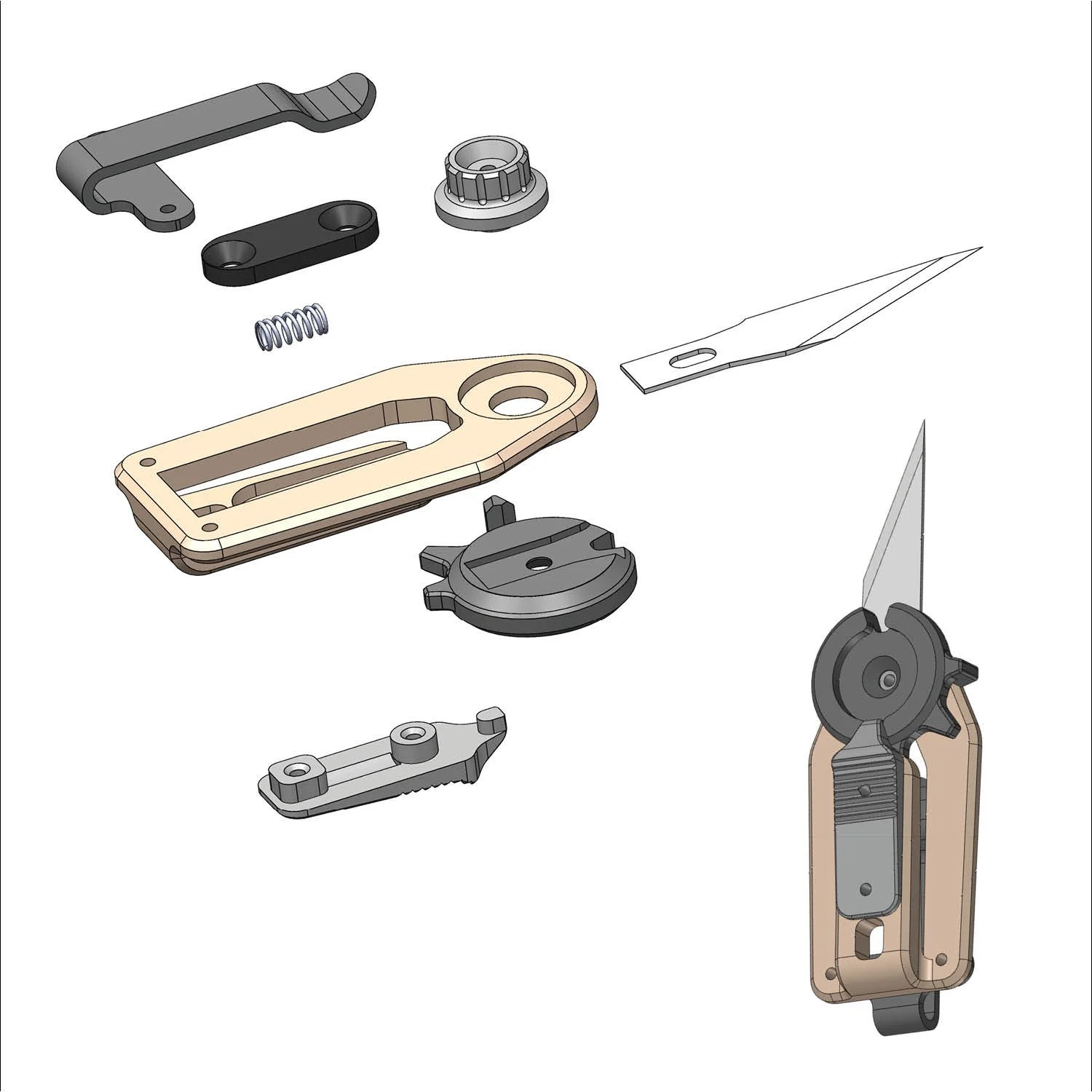

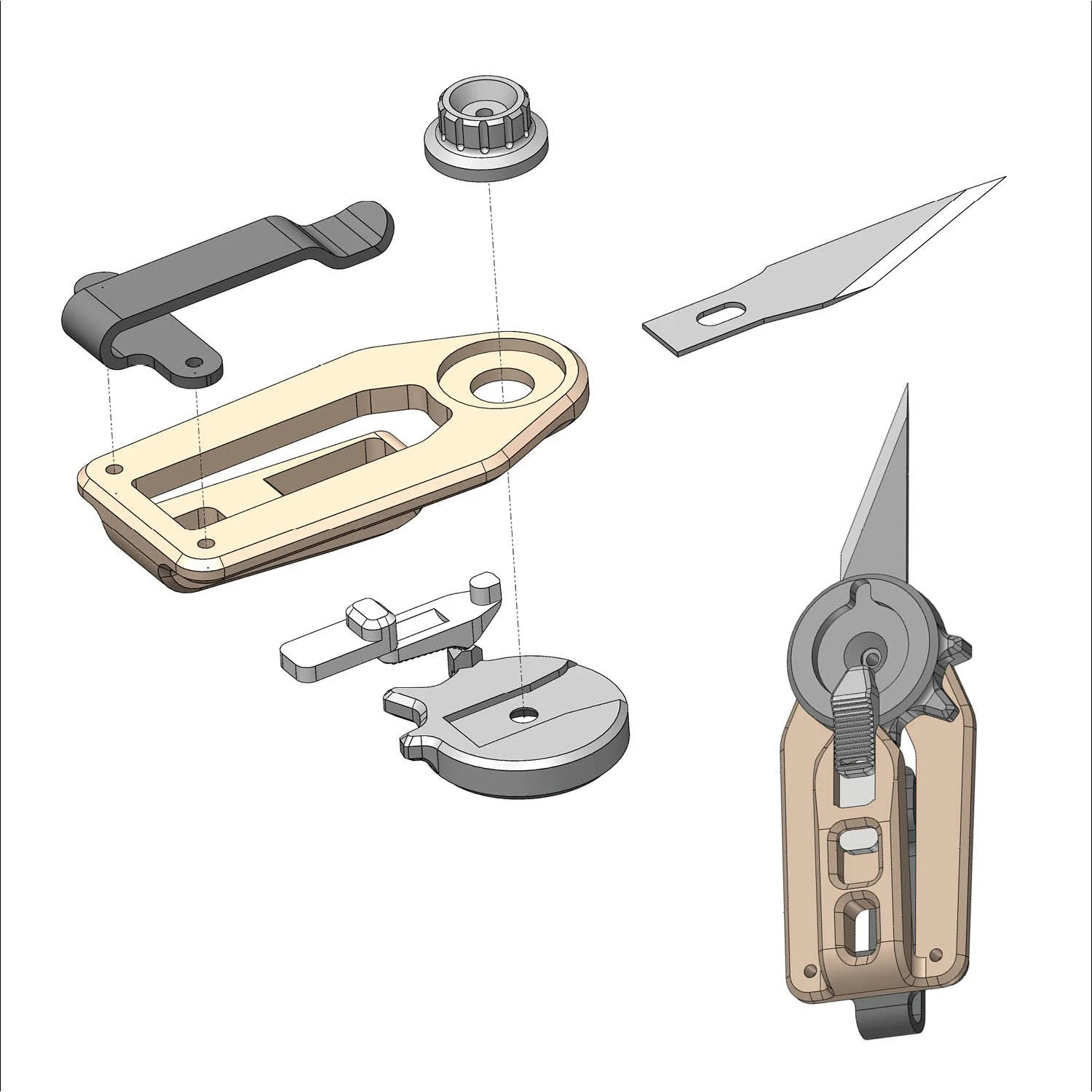

In the CAD phase, our seasoned product development consultancy team leverages cutting-edge engineering software to meticulously engineer and model intricate product designs. We focused on translating the concept into a fully functional 3D model, ensuring the knife’s mechanics and design met all product requirements. We rapidly developed a detailed model with precise dimensions and working components, such as the replaceable blade system and chosen opening mechanism. The team prioritized efficiency, quickly iterating to optimize the design for functionality, durability, and ease of assembly. This phase allowed us to visualize the product's real-world performance, test mechanical functions, and ensure that all parts fit together seamlessly before moving into prototyping.

Step 5: Prototyping

-

In the prototyping phase, we transformed digital designs into tangible prototypes, employing a blend of rapid prototyping technologies and skilled craftsmanship. We produced multiple iterations to test various materials, the opening mechanism, replaceable blade system, and overall ergonomics. Each iteration, was tested for durability, perception of quality, and user comfort. Each prototype underwent rigorous performance testing to ensure the knife could withstand real-world conditions. Feedback from these tests informed future refinements, allowing us to fine-tune the design and material choices for the final product.

-

During the analysis of the first prototyping phase, the team identified several key insights. The polymer 3D-printed prototypes felt too weak for practical use, while the laser-sintered stainless steel prototypes offered a satisfying weight and a high-quality feel. However, assembly of the stainless steel prototype proved challenging, and the soft lock system showed a potential flaw: the knife could accidentally open if enough pressure was applied to the wheel. Additionally, the design wasn’t ambidextrous, and the ergonomics needed improvement.

On the positive side, the compact size made the knife nearly unnoticeable when attached to a key chain, the blade type was extremely sharp and held firmly in place, the blade could be easily replaced and users appreciated the smooth, tactile feedback of the rotating wheel mechanism. These findings guided the next design iterations, focusing on improving safety, ergonomics, and ease of assembly.

Step 6: Refinement

-

The refinement stage is a critical phase in product development where initial concepts are polished into market-ready designs. At Seek Apogee, this stage involves fine-tuning design details, testing materials, ensuring manufacturability, and incorporating user feedback to optimize both functionality and aesthetics. Refinement is essential to maximize product performance, reduce production costs, and mitigate potential risks, all while ensuring the product is ready for mass production. By refining every aspect of the design, we deliver high-quality, reliable, and sustainable products that meet market demands and are ready for launch.

2nd REVISION

-

At the start of the refinement phase, the design team focused on optimizing the second revision by simplifying its construction. We explored integrating multiple components into a single part to improve assembly efficiency and reduce complexity. This streamlined the design while maintaining the knife’s functionality.

The soft lock mechanism was upgraded to enhance safety and reliability, and the knife was made fully ambidextrous to accommodate both left- and right-handed users.

-

During the analysis of the second prototype, the design team identified several improvements and challenges. The built-in pocket clip, made from stainless steel, was found to be too rigid, making it difficult to use effectively. On a positive note, assembly of this prototype was significantly easier due to the integration of multiple parts.

The upgraded soft lock mechanism improved functionality, but there remained a potential issue—if enough pressure was applied to the rotating wheel, the knife could still accidentally open. However, the prototype successfully addressed ambidexterity, making the knife usable for both left- and right-handed individuals. These insights provided valuable direction for further refinements in safety and usability.

3rd REVISION

-

The team moved away from the soft lock mechanism, deeming it unsuitable for such a sharp keychain knife. Instead, a more secure sliding mechanism was explored, featuring a screw-down system with a small plate that encloses a spring on the opposite side to ensure the blade stays locked in place during use and carry. This design prioritized safety while maintaining ease of operation. The team also revisited the mounted pocket clip, refining its design to improve usability without compromising the compact form of the knife.

-

During the analysis of the third prototype, the team identified areas for improvement in the assembly process and functionality. The plate that secured the locking mechanism required significant assembly time and involved too many components, complicating production. Additionally, the blade was not ambidextrous, limiting usability for left-handed users. However, the locking feature attached to the slider worked effectively, engaging with the rotating wheel to securely hold the blade in both open and closed positions. While the locking mechanism was successful in terms of safety, further refinements were needed to simplify assembly and improve ambidexterity.

4th REVISION

-

The team refined the lock engagement system by utilizing the knife's frame to retain the components. By integrating pass-through cores in the frame, the lock mechanism could be secured with a spring, reducing the need for additional parts and keeping the overall part count low. This approach simplified assembly while maintaining a robust and reliable locking system.

-

During the analysis of the fourth prototype, the design team found that the new locking mechanism, integrated with the frame and retained by a spring, successfully reduced the part count and significantly simplified the assembly process. This design improvement enhanced manufacturing efficiency without sacrificing functionality. However, the pocket clip performed well when used independently, but once attached to a key ring, it became difficult to use, limiting the knife’s accessibility and reducing its overall functionality. This feedback highlighted the need for further refinement of the pocket clip design to ensure it works seamlessly in all use cases.

5th REVISION

-

For the fifth revision, the team focused on optimizing the knife’s ergonomics and improving grip features on key user touchpoints for enhanced comfort and control. The actuation mechanisms were refined for smoother, more intuitive operation. The pocket clip, which had proven impractical in previous iterations, was removed to simplify the design and improve functionality. Additionally, a solution was implemented to make the knife fully ambidextrous, allowing both left- and right-handed users to easily operate the knife. These changes aimed to improve overall user experience and performance.

-

During the analysis of the fifth prototype, the team found that assembly was more simple and faster. The wider grip significantly improved both comfort and usability, providing better control for users. However, the locking mechanism felt too loose during testing. This was due to the nature of the prototype materials and the single locking interface feature. This feedback highlighted the need for further refinement of the locking system to ensure a tighter, more reliable engagement and shown it was time to utilize prototyping processes with tighter tolerances.

6th REVISION

-

For the sixth revision, the team further enhanced the user touchpoints, improving ergonomics and grip for a more comfortable and secure hold. A secondary locking interface was added to the locking mechanism to address previous issues with looseness, ensuring a more secure blade engagement. Alongside these refinements, the team began designing the individual parts with manufacturing in mind, optimizing components for production and efficiency.

-

In the analysis of the sixth prototype, the team found that the updated locking mechanism significantly improved blade stability, resulting in almost zero wiggle when the knife was locked open or closed. The new prototyping process, with tighter tolerances, produced parts that closely matched the 3D models and aligned with what would be expected from our selected production manufacturing method. With these improvements, the knife was considered highly refined and ready for broader user testing. The team planned to gather feedback from potential users in the actual target market to ensure the design met real-world expectations before moving toward final production.

7th REVISION

-

During the concept development of the seventh revision, the team integrated invaluable feedback gathered from potential customers in the target market. Many users expressed a preference for a closed-off back on the knife for a more improved safety and to prevent debris from entering. Additionally, there was strong demand for the return of the pocket clip for enhanced portability and ease of use. Users also requested more thumb room on the opening mechanism for easier operation. Based on this feedback, the team decided to implement all of these changes, ensuring the knife better aligned with customer desires while maintaining its functionality and sleek design.

-

In the analysis of the seventh prototype, the team found that incorporating user feedback greatly enhanced both functionality and usability. The closed-back design, added pocket clip, and increased thumb room on the opening mechanism made the knife more practical and user-friendly. When the revised design was shown to the same target market group, it received strong approval, confirming that the changes addressed their needs and expectations. The product was now well-aligned with market demands, signaling readiness for final development steps.

Step 7: Design for Manufacturing and Production

-

In the Design for Manufacturing (DFM) and Production stage, we focused on optimizing the design specifically for efficient manufacturing. We produced detailed engineering drawings that specify dimensions, tolerances, and materials for each component. A comprehensive Bill of Materials (BOM) lists all necessary parts and quantities, streamlining procurement.

We also created clear assembly instructions to ensure a smooth manufacturing process, alongside manufacturing process plans that outline the recommended techniques and equipment. Prototyping specifications were developed to facilitate testing of the design prior to full-scale production, while quality assurance plans define the criteria to guarantee that each knife meets our high standards.

Our cost analysis helps keep production within budget, and supplier recommendations ensure the sourcing of quality materials and components. Additionally, we provide compliance documentation to meet industry standards and regulations.

Every aspect of the knife's design is optimized for its specific manufacturing process, ensuring not only exceptional functionality and usability but also a smooth transition from concept to a market-ready product.

Step 8: First Article Evaluation and Tool Adjustment

-

During the First Article Evaluation and Tool Adjustment stage, we take critical steps to ensure that the manufacturing process aligns with our high standards of quality and consistency. In this phase, we order the necessary tooling and manufacture the first article parts, which serve as initial production samples. These samples are rigorously tested to evaluate their performance and functionality, ensuring they meet all design specifications and user requirements. We assess factors such as fit, finish, and durability, allowing us to identify any potential issues early in the production process. we fine-tune the tooling based on the results of these tests, making necessary adjustments to optimize manufacturing efficiency and consistency. This iterative approach ensures that each component can be reliably produced at scale, meeting our commitment to quality and performance.

-

During the First Article Evaluation and Tool Adjustment stage, the team focused on fine-tuning the manufacturing process to ensure consistent product quality. After testing the first article parts, adjustments were made to the tooling to enhance the lock mechanism, giving it a more robust feel. The team also optimized the metal flow to ensure proper filling of the mold cavities, preventing defects. The tooling texture were also refined to improve part release after molding, streamlining the production process.

Step 9: Quality Control of full Production

-

During the Quality Control of Full Production phase, the full production run was initiated, and rigorous quality control measures were implemented to ensure every part met the required specifications. Throughout the production process, parts were consistently measured for accuracy, with key dimensions and tolerances carefully inspected to maintain the highest quality standards. This ongoing monitoring helped identify any deviations early on, ensuring that each knife produced was reliable, functional, and consistent with the design intent. These quality control efforts ensured that the final product delivered exceptional performance and met the expectations of the market.

Step 10: Assembly Tool Design for Stud Pressing

-

The team developed a specialized tool to streamline the assembly process for the client's knife production. The client needed a tool that could press a stud into the screw head for up to four screws at a time, using a benchtop press. To meet this requirement, the team designed a tool that self-centers the cross pattern on each screw, minimizing the chance for assembly errors. The tool features linear bearings to ensure smooth operation and automatically extends back up when the press is retracted.

This tool was essential because the knife was being manufactured in the USA, and reducing manual labor in the assembly process was a priority for cost efficiency. Since it was the first production run, a low-cost, manually operated solution was developed instead of a more expensive robotic or pneumatic system, balancing quality and budget while improving

Step 11: Crowdfunding Campaign Video Creation

-

We handled every aspect of production for the crowdfunding campaign video. This included scripting the video to highlight the knife’s key features, benefits, and unique design. We shot high-quality footage on a tight budget, capturing detailed product shots, user interactions, and lifestyle scenes. Professional editing was applied to create a compelling narrative, integrating engaging visuals, motion graphics, and sound design to ensure the video resonated with potential backers and effectively conveyed the product’s value.

Step 12: Crowdfunding Campaign Page Creation

For the Crowdfunding Campaign Page Creation on Kickstarter and Indiegogo, we developed every aspect of the page from start to finish. This included crafting engaging copy to tell the product’s story, highlight its key features, and emphasize its value to potential backers. We designed visually striking graphics and infographics to showcase the knife’s unique attributes and developed reward tiers to encourage different levels of support. The page layout was optimized for clarity, ensuring a seamless user experience that motivates visitors to back the project.

Step 13: Retail Packaging Design

-

We analyzed industry standards to ensure the packaging met both functional and aesthetic expectations for the retail market. The package was designed to hang from a hook and face the customer, featuring two thermoformed plastic pieces to provide secure protection for the knife during shipping and handling. The front of the packaging graphics were carefully crafted to display the contents, including the knife, a blade box with six replacement blades, and a bottle opener, all while maintaining the brand’s distinctive style.

-

The design of retail packaging is an important aspect of the product development process because it serves as the first point of interaction between the customer and the product. Effective packaging not only protects the product during shipping and handling but also enhances its visual appeal, attracting attention on store shelves or online platforms. Well-designed packaging communicates the brand’s identity, key product features, and benefits, and influences purchasing decisions.

-

For the back of the retail packaging, we focused on creating clear, informative graphics. The packaging included step-by-step instructions on how to open the knife, replace the blade, and switch the blade for left-handed use. The design also highlighted the pocket clip feature, showcasing its functionality. These visuals were crafted to ensure that customers could quickly understand how to use and maintain the knife, enhancing the overall user experience while reinforcing the product's versatility and ease of use.

Step 14: Point of Purchase Design and Creation

-

A Point of Purchase (POP) display is essential for selling a product because it grabs the customer’s attention and creates a memorable visual impact, especially in crowded retail or event spaces. It provides an opportunity to showcase the product's key features and benefits in a way that stands out from the competition. A well-designed POP display also encourages customer interaction, leading to increased engagement and higher sales potential. By highlighting the product's value and making it more accessible, a POP display plays a crucial role in influencing purchasing decisions and enhancing brand visibility.

-

During the Point of Purchase Design and Creation phase, we developed a striking multi-level pyramid display intended to capture attention at in-person shows. Each level of the pyramid featured built-in lighting beneath, highlighting the products and creating a visually appealing glow. At the top, a jewel-like holder was designed to elegantly present the knives, making them the focal point of the display. The structure was carefully crafted to be both eye-catching and functional, strategically designed to draw in passersby and encourage interaction with the product. The display effectively combined form and function, showcasing the knives in a way that stood out in busy event environments.

Full Scope of Work

Product Development Process

- Market Research & Competitive Analysis: Studied the market landscape and competition to identify opportunities and user preferences.

- Demographic Research: Identified the target audience and their specific needs and preferences for the knife.

- Ideation: Focused on the Minimum Viable Product (MVP), exploring various opening mechanisms, materials, manufacturing processes, and optimizations.

- CAD Development: Created fully functional designs with working mechanics, ensuring they met all design requirements quickly.

- Prototyping: Developed multiple prototypes using various materials and mechanics, testing for functionality and durability.

- Prototype Analysis: Identified strengths and weaknesses, including material strength, ease of assembly, ergonomics, locking mechanism performance, and user feedback.

- Concept Development: Refined design features, including locking mechanisms, ambidextrous usability, and ergonomic improvements.

- Quality Verification and Tooling Enhancement: Ordered tooling, manufactured first article parts, adjusted tooling for optimal metal flow, and improved assembly processes.

- Assembly Tool Design: Developed a custom tool for efficiently pressing studs into screw heads, designed for the first production run to reduce manual labor.

- Retail Packaging Design: Created packaging with protective thermoformed plastic, optimized for hanging display, and designed graphics to showcase the product and brand.

- Point of Purchase Display Design: Designed an eye-catching, multi-level pyramid display with integrated lighting and a jewel-like knife holder for in-person shows.

- Full Production Quality Control: Measured and inspected production parts to ensure they met all design and quality standards.

Branding

- Logo Creation: Designed a distinctive logo that captures the essence of the product and brand identity.

- Brand Style Guide: Developed a comprehensive guide covering color schemes, typography, and visual identity for consistency across all platforms.

- Product Naming: Crafted a memorable, market-ready name for the pocket knife, aligning with the brand’s image and values.

Crowdfunding Campaign Creation

- Campaign Strategy: Developed a strategic plan to engage backers, set funding goals, and communicate the product’s value proposition.

- Campaign Copywriting: Wrote compelling descriptions and engaging stories that highlight the features, benefits, and uniqueness of the knife.

- Reward Structure Development: Designed tiered reward packages that incentivize backers at multiple levels.

- Campaign Graphics & Design: Created visually striking campaign visuals, including banners, infographics, and product renders.

Videography & Photography

- Concept Development: Planned and scripted the campaign video to showcase the knife’s features, benefits, and use cases.

- Product Photography: Conducted high-quality photo shoots, capturing detailed images of the product for use in marketing, packaging, and the website.

- Lifestyle Photography: Created lifestyle images that demonstrate the knife in everyday use, appealing to the target audience.

- Video Production: Shot and edited a professional campaign video, incorporating product demos, user testimonials, and engaging visuals.

Website Design

- Wireframing & Prototyping: Developed wireframes and prototypes for an intuitive, user-friendly website.

- Responsive Design: Created a fully responsive design optimized for desktops, tablets, and mobile devices.

- Content Development: Wrote engaging copy to highlight the product’s features, the brand’s mission, and campaign details.

- E-Commerce Integration: Integrated a secure payment gateway for direct sales, allowing users to purchase or back the project seamlessly.

- SEO Optimization: Optimized the website for search engines to drive organic traffic.

Business Development

- Market Entry Strategy: Defined a clear strategy for introducing the product to the market, targeting key retailers and online platforms.

- Partnership Development: Identified and established relationships with potential partners, distributors, and suppliers.

- Cost and Pricing Analysis: Conducted a thorough cost analysis to determine the most competitive and profitable pricing model.

- Long-term Business Planning: Developed plans for scaling the business, launching future product lines, and sustaining market growth.

- Customer Support Plan: Established customer service protocols to handle inquiries, product feedback, and post-launch support.